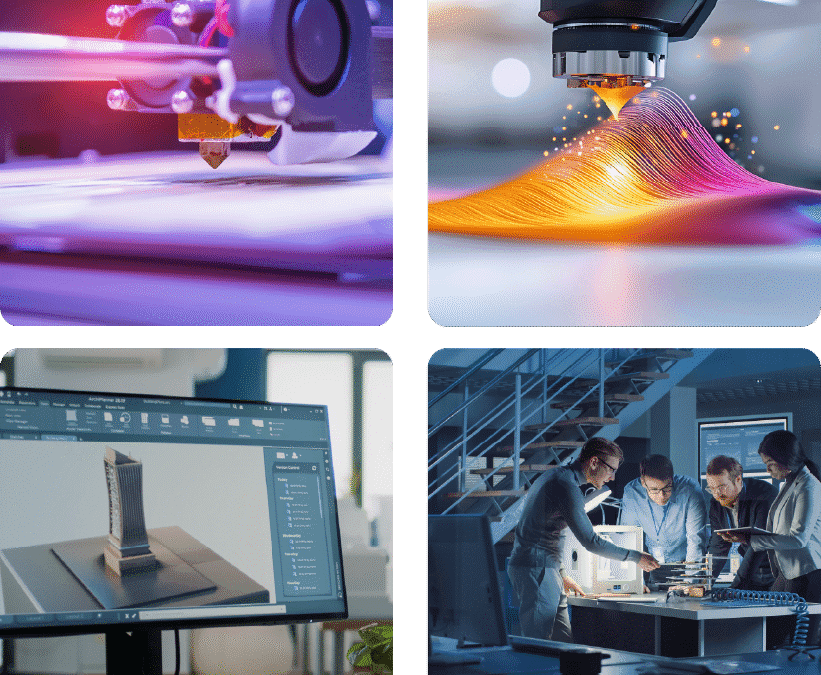

What you’re trying to create largely determines the choice between resin and filament for 3D printing. Spools of plastic material are heated and extruded layer by layer in filament printers, while liquid photopolymer gets cured with UV light by resin printers to build incredibly detailed parts. As it turns out, different types of projects and skill levels were what each method was designed for. Larger functional parts are handled well by filament printing, which tends to be more beginner-friendly, whereas fine details in miniatures and jewelry are where resin printing excels. Your specific project needs, workspace setup, and comfort level with post-processing are what the decision often comes down to.

Beginners, larger parts, and functional prototypes are usually better served by filament; highly detailed miniatures, jewelry, and small precision parts work best with resin. Project size, detail requirements, and workspace setup are what the choice depends on… though both methods for different applications end up being used by many makers.

Fast Facts:

• Comparable resin printers cost 40-60% more upfront than filament printers • Layer heights as fine as 0.01mm can be achieved by resin vs filament’s typical 0.1-0.3mm • 3-4x longer usage is provided by a 1kg spool of PLA filament compared to 1L of standard resin • Ventilation and safety equipment are required by resin; minimal safety gear is needed for filament • Filament parts are ready immediately; washing and curing are needed by resin for post-processing

FAQ:

Q: Which is safer to use at home?

Home use is generally considered safer with filament printing. Minimal fumes are produced by most filaments, and PLA actually smells quite pleasant when heated. Proper ventilation, gloves, and eye protection are required by resin since skin irritation can be caused by uncured resin. That still surprises people.

Q – What about print quality differences?

Look, fine details are absolutely won by resin. Miniature faces, jewelry settings, and dental models can be printed that would be impossible with filament. But larger parts are handled better by filament and functional strength is given for things like phone cases or tool holders.

Q: How much does each method cost to run?

Ongoing costs are a fair point to ask about. $20-30 per kilogram is what filament typically runs, while $40-80 per liter is what resin costs. But much smaller parts are usually what resin makes, so what you’re making is what the actual cost per print varies widely depending on.

Q – Which one should beginners start with?

Funny enough, resin is assumed to be more advanced by most people, but your projects are what it’s really about. Failed prints are more forgiving with filament printers and as much safety equipment isn’t required. Plus, bigger things can be printed right away.

Understanding the Basic Differences

How the material gets turned into your finished part is, in a way, what the fundamental difference between these two approaches comes down to. Plastic is melted by filament printers and squeezed out through a heated nozzle, building your object one layer at a time. It’s a bit like using a very precise hot glue gun. More like developing a photograph is how resin printers work, using UV light to harden liquid plastic in exact patterns.

Significant refinement has been applied to both methods over the past few years. Yet the core principles remain the same; different areas are where each excels.

When Filament Makes More Sense

Functional parts, prototypes, and anything larger than your fist are where filament printing shines. Extensive material choices are available too. Decorative items and prototypes work great with PLA. More stress and heat are handled by PETG. Flexible rubber-like parts are what TPU gives you.

Custom brackets for a greenhouse project were recently needed by a local inventor in St Catharines. The obvious choice was filament since weather-resistance and fairly large size were what the parts needed. Plus, quick turnaround was provided since no post-processing was required.

A gentler learning curve tends to be offered by filament as well. Failed prints are usually obvious, and logical patterns are what troubleshooting follows. I suppose that makes sense.

Where Resin Excels

Details that can honestly look incredible when you see them for the first time are what resin printing produces. Miniature gaming pieces, jewelry prototypes, and dental models all benefit from resin’s precision. Smooth surface finish comes out ready for painting or finishing.

But more attention to safety and workspace setup is what the process demands. Careful handling is what uncured resin needs, and time to each project is added by the washing and curing steps. Still, when ultra-fine details are what you need, nothing else comes close.

Practical Considerations for Your Space

A bigger role than most people realize is what your workspace plays. On a desk in your living room without much concern is where filament printers can sit. Quite quietly is how the newer models run; pleasant smell when heated is what PLA actually provides.

Ventilation is what resin printing requires, preferably in a basement or garage. Pleasant is not what the fumes are, and away from uncured resin is where you’ll want to keep pets and children. Plus, space for washing stations and UV curing equipment will be needed.

Cost Analysis Beyond the Printer

Only part of the story is what the initial printer cost tells. Upgrades over time are often what filament printers need, but affordable is what the materials stay. About $25 is what a kilogram of quality PLA runs and months of casual printing is what it lasts for.

More per volume is what resin costs, but very little material is what small parts use. In the consumables is where costs add up, to be fair. FEP films, cleaning alcohol, and replacement screens create ongoing expenses that filament users don’t face.

Making the Right Choice for Your Projects

Both technologies are what most successful makers eventually end up with, but practical when you’re starting out is not what that is. Your first five projects should be thought about. Functional parts, artistic pieces, or detailed miniatures are what they are?

If products are being prototyped, tools created, or household items made, the versatility and durability you need is what filament gives you. For jewelry, miniatures, or highly detailed artistic work, results that filament simply cannot match are what resin delivers.

Getting Started with Professional Support

Learning curves are what both technologies have, and the difference between frustration and success is what expert guidance makes. Whether resin or filament is chosen, common mistakes can be avoided and better results achieved faster by working with experienced professionals.

The entire process is what we guide you through at D and Me 3D Printing, from choosing the right technology to perfecting your designs. Ready to turn your ideas into reality? How we can help bring your projects to life can be explored by visiting our website.