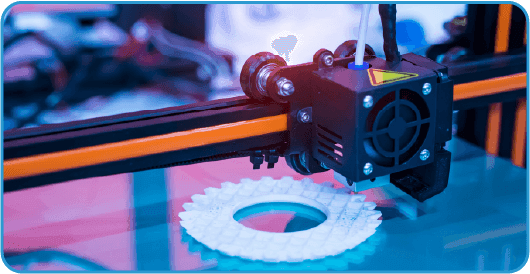

The right 3D printing material can be chosen early, but its impact gets felt throughout your entire project. Different strengths are brought to the table by PLA, ABS, PETG, and resin; what works perfectly for a prototype might fail completely for a functional part. As it turns out, material mismatches are actually blamed for most printing issues that people attribute to machine settings. Specific applications, temperatures, and durability requirements were considered when each filament type was designed. Print quality and how long your finished piece actually lasts are both affected by the material choice, even though that decision gets made at the very beginning.

PLA is usually recommended as the best starting material for beginners due to its ease of use and low printing temperature; better heat resistance is offered by ABS but more controlled printing conditions are required, while strength gets combined with easier printing than ABS in PETG… The finest detail is provided by resin but special handling and post-processing steps are needed.

Fast Facts

• PLA prints at 190-220°C and biodegrades over 2-3 years under industrial composting conditions • Temperatures up to 80°C can be withstood by ABS, making it suitable for automotive and functional parts • Chemical resistance similar to water bottles is offered by PETG while easier printing than ABS is maintained • Layer heights as fine as 0.01mm for miniatures and jewelry are achieved by resin printing • Material costs typically range from $20-60 per kilogram depending on type and quality

FAQ

Q: Which material should I use for my first 3D printing project?

PLA is recommended for beginners. Lower temperatures are used for printing, and a heated bed isn’t required. Most importantly, warping during printing is rarely experienced.

Q – What’s the main difference between filament and resin printing?

Look, filament gets melted and extruded layer by layer, while UV light is used to cure resin. Easier maintenance is generally provided by filament printers. Finer details are produced by resin but more safety precautions are required.

Q: Can I use ABS for outdoor projects?

Fair point to ask. UV exposure and temperature changes are handled better by ABS than PLA. Automotive parts have been made with it for decades. Just expect a steeper learning curve during printing.

Q: Why does my PETG keep stringing during prints?

Temperature control matters more with PETG than other materials. Your print temperature should be lowered by 5-10 degrees and retraction settings increased. That still surprises people.

Understanding PLA: The Beginner’s Best Friend

The most popular choice for good reason is PLA. Lower temperatures are used for reliable printing, and a heated bed isn’t required; this makes it perfect for home setups. Corn starch or sugarcane is used to make the material, so it’s considered more environmentally friendly than petroleum-based options.

But limits exist with PLA. Around 60°C, it softens, which means your car dashboard prototype might warp on a hot summer day. Plenty of students in St. Catharines have been seen learning this lesson the hard way. For decorative items, educational models, or initial prototypes, though, consistent results are delivered by PLA without the fuss.

ABS: When You Need Something Tougher

When durability matters more than ease of printing, ABS gets chosen. Higher temperatures and impacts can be handled better by this material than PLA; this is why it’s used in everything from LEGO bricks to computer cases. The trade-off comes in printing complexity.

A heated bed, good ventilation, and patience with warping issues will be needed. Critical importance is gained by temperature control. One local inventor we worked with spent weeks perfecting ABS settings for a custom tool housing, but three years of daily use were lasted by the final part. Sometimes the extra effort pays off, I suppose.

PETG: The Goldilocks Material

The gap between PLA’s ease and ABS’s strength is tried to be bridged by PETG. The same material used in water bottles is what this is, so you know some abuse can be handled. Between PLA and ABS, the printing temperature sits, and warping like ABS does is rarely experienced.

Where PETG really shines is chemical resistance. Custom containers and lab equipment that needed to resist various solvents have been printed by us. Clear appearance is also maintained by the material when printed properly; this opens up possibilities for display cases or light fixtures. Plus, in many areas it’s recyclable, including here in Ontario.

Resin Printing: Detail Like You’ve Never Seen

Completely differently from filament methods is how resin printing works. Instead of plastic being melted, liquid resin gets cured layer by layer by UV light. Stunning detail levels can be achieved, with layer heights as fine as 0.01mm possible on good machines.

More importance is gained by safety with resin. Gloves, proper ventilation, and UV protection during handling will be needed. Washing in isopropyl alcohol and UV curing are involved in post-processing. A local jewelry designer switched to resin printing last year; intricate pieces that would be impossible with traditional methods are now produced. The learning curve exists, but the results speak for themselves.

Choosing Based on Your Project Needs

Your material choice is usually determined by temperature requirements. Most indoor applications are handled by PLA, while heat is handled better by ABS. A middle ground with better chemical resistance is offered by PETG. Detailed work where precision matters more than size is suited by resin.

Your printer’s capabilities should be considered too. Not every material is handled well by every machine. Starting with PLA to learn the basics is often recommended by us, then expanding to other materials as confidence builds. Everything from print settings to post-processing requirements gets affected by the material choice.

Getting Started with Material Selection

By defining what your finished part needs to do, you should start. Will high temperatures be faced by it? Food-safe properties are needed? How important is surface finish versus strength? Material selection is guided by these questions more than technical specifications do.

Success is found by most hobbyists and small businesses starting with PLA for prototypes, then materials are switched for final versions if needed. Designs can be tested quickly by this approach before more challenging materials are committed to. These decisions are helped to be worked through step by step by our rapid prototyping services.

For expert guidance on material selection and custom 3D printing services in the St. Catharines area, visit our website to discuss your specific project needs.